- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

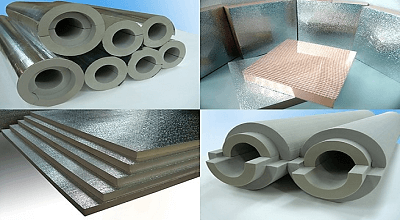

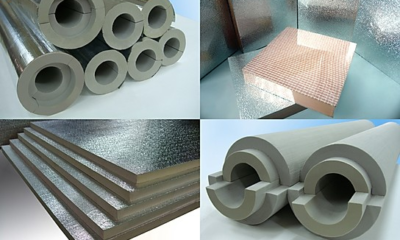

Rigid Foam Insulation

Rigid foam Insulation

Product Details:

Expanded polystyrene (EPS) is made up of beads of polystyrene. Small solid particles of polystyrene are made from the monomer of styrene.

This polystyrene normally solid at room temperature . That can be melted at a higher temperature and re solidified for desired application. Expanded polystyrene volume is about 40 times to the original volume. EPS is lightweight closed cell cellular plastic material.

Product Details:

Expanded Polystyrene preformed pipe section is a tough, rigid, light weight, closed cell insulation foam commonly known as EPS. Normally having density from 8 Kg/M3 to 32 Kg/M3. Its close cell structure provides low water vapor permanence and hence it is widely used for thermal insulation. In food container, packaging industries, Building Insulation, Chilled water piping, refrigeration and many more.

| Densities (Kg/M3) | 8 to 32 |

| Pipe Diameter | 1/2″ to 24 “ |

| Thicknesses in (mm) | 25, 40, 50 , 65,75, 100 |

| Dimensions | 1 Mtr L |

| USES: |

|

| Special Note : | Also Available in TF Fire retardant Grade |

Product Details:

Expanded Polystyrene sheets is a tough, rigid, light weight, closed cell insulation foam commonly known as EPS. Normally having density from 8 Kg/M3 to 32 Kg/M3. Its close cell structure provides low water vapor permanence and hence it is widely used for thermal insulation. In food container, packaging industries, Building Insulation, Chilled water tank, refrigeration and many more.

| Densities (Kg/M3) | 8 to 32 |

| Pipe Diameter | 1/2″ to 24 “ |

| Thicknesses in (mm) | 25, 40, 50 , 65,75, 100 |

| Dimensions | 1 Mtr L |

| USES: |

|

| Special Note : | Also Available in TF Fire retardant Grade |

Product Details:

Polyurethane foam is basically polymer, which is form when Isocyanate and Polyol is reacted. These compounds are mixed and pour into mold to form a rigid, cellular foam. Resultant material is light weight polymer with excellent insulating property.

| Densities (Kg/M3) | 36 to 40 Kg/M3 |

| Pipe Diameter | 1/2″ to 24 “ |

| Thicknesses in (mm) | Pipes : 25 -100 |

| Temperature Range | -40 Deg C to 110 Deg C |

| USES: |

|

Product Details:

Polyurethane foam is basically polymer, which is form when Isocyanate and Polyol is reacted. These compounds are mixed to form a rigid, cellular foam. Resultant material is light weight polymer with excellent insulating property.

| Densities (Kg/M3) | 36 to 40 Kg/M3 |

| Cell structure | Closed Cell |

| Thicknesses in (mm) | 15 – 300 |

| Dimensions | Block:1 Mt L X 0.5 mt W |

| Temperature Range | – 40 Deg C to 110 Deg C |

| Thermal Conductivity (W/mk) | 0.021 @ 10 Deg C |

| USES: |

|

Product Details:

Insulation Pipe Support are designed to prevent direct Insulation Pipe Support are designed to prevent direct heat transfer between Pipe and tank through their Support. Thus it reduces conduction at each support.

The support are not welded, each unit is shipped completely assembled. (Except Riser and Anchor Support) Normally the density of puff support Density is vary from 100 Kg/M3 to 350 Kg/M3 in some special case it can be up to 500 K/M3

| Densities (Kg/M3) | 100-140 Kg/M3(Available higher Densities in special case) |

| Pipe Diameter | 1″ to 14″ |

| Thicknesses in (mm) | 75, 100 mm |

| Advantages: |

|

Product Details:

Phenolic foam is a rigid cellular foam insulation material. Its polymer structure is made up from poly-condensation of phenol. It is a closed Cell material. Phenolic Foam is Non Flammable rigid insulation foam. It is untouched by fire, When it comes in contact of fire it turns dark Brown and retains its shape. Phenolic foam does not emit any toxic fumes or gases.

| Densities (Kg/M3) | 35 to 40 Kg/M3 |

| Cell structure | Closed Cell |

| Thicknesses in (mm) | Pipe : 20,25,30,40,50 |

| Color | Block : 1 Mt L X 0.5 Mt W , 4’X 2’ | Light Green |

| Facing | Kraft Paper/ Aluminum Foil/ Glass Cloth/ Glass Mat/ Decorative Paper & Laminates |

| Temperature Range | -196 to 130 Deg C |

| Thermal Conductivity | 0.017 W/mk |

| USES: |

|

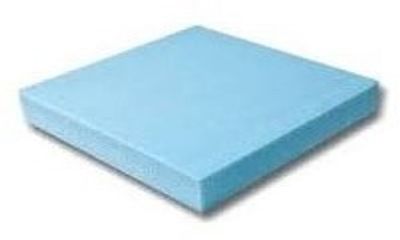

Product Details:

Extruded Polystyrene (XPS) Thermal Insulation Board is a rigid foam board having closed cell structure and is produced in a fully automated continuous extrusion process. Unique property of XPS boards is high compressive strength, higher R- Value, Low water vapor absorption.

| Densities (Kg/M3) | 34 Kg/M3 |

| Cell structure | Closed Cell |

| Thicknesses in (mm) | Pipe : 20,25,30,50,75 & 100 |

| Dimensions | 1250 mm X 600 mm |

| Thermal Conductivity | 0.0289 W/mk |

| R – Value | 0.88 K m2/W |

| Water Vapor permanence | 63 Ng Pa.s.m2 |

| Water Absorption | 0.3% by volume |

| USES: |

|

Sheth Insulations Private Limited is a distributors of polyurethane foam insulation. The company provides industrial, commercial and residential insulation services. Sheth’s products are used in the construction industry as an alternative to traditional materials such as concrete, stone, brick or wood for thermal protection. We are leading company that provides cold insulation materials. The company has been in business for many years and their products are used by major construction companies all around the world. Their insulation material is environmentally friendly, durable, and has many other benefits such as being fire retardant and having a high thermal resistance rate.

"We are at SIPL, provide our customers with quality insulation materials at the most competitive price. Customer is the Priority, and their satisfaction is our aim."

City Office

705, Iconic Shyamal, Shyamal Char Rasta, Ahmedabad, Gujarat 380015

Godown Cum Office

No. 402/B, Phase- 2, G.I.D.C., Vatva, Ahmedabad, Gujarat, India - 382445