- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

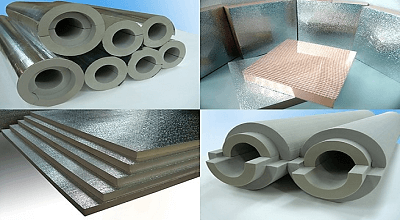

Insulation Jacketing

Insulation Jacketing

The key role of Jacketing is to control penetration of weather element and ingress of water. It also provides mechanical strength to the insulation the jacket also serves to establish the system emissivity and appearance.

While selecting insulation jacketing must consider the mechanical, thermal, chemical and moisture conditions of the installation. Cost and aesthetical requirement also has to be considered.

Metallic Jacketing

Insulation is covered by metal jacketing like Aluminum, Stainless Steel, Coated steel, Aluminized steel, Galvalume steel, and Zinc galvanized steel. Metal jackets come lined with bonded polykraft paper or polysurlyn.

Product Details:

Aluminum sheet are widely used in fabricating metal Insulation jacketing. Aluminum is light weight, flexible to fabricate easily at site and has good resistance to corrosion. Apart from this Aluminum has many characteristics due to which it is commonly used as a insulation jacketing metal.

| GUAGE | THIKNESS (MM) | WEIGHT (KG) PER SQ. M |

| 18 | 1.22 | 3.32 |

| 20 | 0.91 | 2.47 |

| 22 | 0.71 | 1.93 |

| 24 | 0.56 | 1.52 |

| 26 | 0.46 | 1.25 |

| Advantage: |

|

|

Product Details:

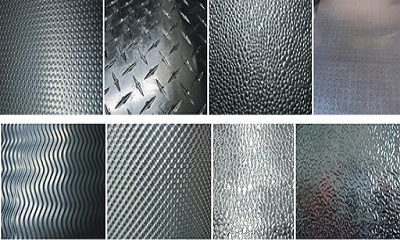

Aluminum sheet are widely used in fabricating metal Insulation jacketing. Aluminum is light weight and having good resistance to corrosion.

The term corrugated, describing a series of parallel ridges or furrows. There are two types of corrugation, circular and trapezoidal. Corrugation describe in terms of, pitch and depth, It is important that depth and the pitch to be quite uniform to be easily stackable and to overlap neatly on joints

| INDUSTRIAL TROUGHED SHEET | CIRCULAR CORRUGATED SHEET | |

| Standard Width | 795 mm, 920mm, 1044 mm | 800mm, 950mm, 1250mm |

| Preferable Width | 1044 mm | 1250 mm |

| Length | As per your requirement | As per your requirement |

| Thickness Available | 1.22mm,0.91mm,0.71mm,0.56mm | 1.22mm,0.91mm,0.71mm,0.56mm |

| Preferable Thickness | 0.71mm (22 – gauge) | 0.71mm (22 – gauge) |

| Advantage: |

|

|

Product Details:

Aluminum Stucco sheet has rugged surface which reduce light reflection and glare, due to its embossed pattern which reduces vibrations’ it provides additional mechanical strength to the sheet

| Advantage: |

|

Product Details:

Aluminum sheet coated with moisture retarders: Layer of plastic film or other material applied to the inner side of metal jacketing to inhibit jacket corrosion by interfering with the formation of a galvanic cell between the dissimilar metal of the pipe and jacket or by preventing crevice corrosion.

Aluminum with Poly Kraft Coating: A multilayer composite film used as s moisture retarder on metal jacketing consisting of at least one layer of minimum 40 LB Kraft Paper and one or more layers of plastic film, usually polyethylene at a minimum thickness of 1.5 mils.

Aluminum Sheet coated with Polysurlyn : A multilayer film used as a moisture retarder on jacketing consisting of at least one layer of acid copolymer surlyn and one or more layers of other polymers, usually polyethylene.

| Physical Property Of Polysurlyn Moisture Barrier And ASTM Test Method | Value | ASTM C1729 Requirement |

| Pinholes, C1729, number per 50 ft2 | 3 mil (76) | 3 mil (76) |

| 0 | <5 | |

| Water Vapor Transmission Rate F1249, 0/100% r. h., 730 F (g/100 ind – day) | 0.048 d | <0.1 |

| Water Vapour Transmission Rate F1249, 0/100% r. h. , 1000 F (g/100 ind – day) | 0.19 d | – |

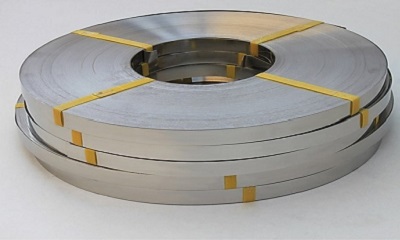

Product Details:

Stainless steel are notable for their corrosion resistance, Which increases with increasing chromium content. Addition of Molybdenum increase corrosion resistance in reducing acids and against pitting attack in chloride solutions. Thus there are numerous grade of stainless steel with varying chromium and molybdenum contents to suit the environment the alloy must endure.

Stainless steels resistance to corrosion and staining, low maintenance, and familiar luster make it an ideal material for many applications where both the strength of steel and corrosion resistance is required.*

Normally available in two grades

- SS 304

- SS 316

Product Details:

Aluminum foil is used

1) As a Vapor Barrier

2) For the Corrosion Protection over SS Surface.

Vapor Barrier: In cold Insulation Process to avoid sweating or condensation. Aluminum foil is used in between insulation and jacketing application as a vapour barrier.

Corrosion Protection over SS Surface: Aluminum Foil is applied before Insulation over the surface of Stainless steel vessel / pipes to avoid corrosion. SS Surface when directly come in contact to mineral it cause corrosive action to avoid this foil is applied.

| Aluminum Foil | 7 micron |

| Adhesive | 8 g/M2 |

| Tri-way Fiber Glass | 8/100 mm (MD) |

| 12/100 mm (XD) | |

| Flame Retardent Draft | 65 G/M2 |

| Basic Weight | 80 G/M2 |

| Tensile Strength | 3.5 kn/m(MD) |

| 3.3 kn.m (XD) | |

| Burst Strength | 200 KPA |

| Water Resistance | No lekage Phenomenon |

| Low Temperature Resistance | -40 Deg C |

| High Temperature Resistance | 116 Deg C |

| Resistance Thickness | 130 Microns |

Product Details:

Other than metals, thermoplastic and flexible fabrics are also important jacketing material.

Thermoplastic jackets are generally not preferred due to their poor resistance of fire, how ever wide variety of fabric made from Fiber Glass & Ceramic with special coatings are used in different types of jacketing over insulation.

Product Details:

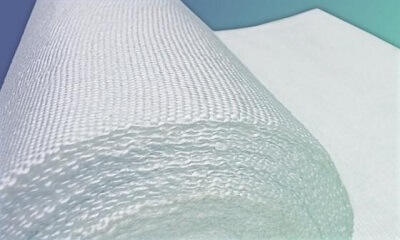

The thin, continous and multi fiber filaments are process through reinforcment and woven to form fiberglass fabric.

This fiber glass fabric is light weight and versatile material with high heat resistance.

| Material | Fiber Glass |

| Type | Mesh |

| Colour | Silver |

| Thickness | 5 mill |

| 5 Mill Thickness | 150 GSM |

| Type of Weave | Plain |

| USES: |

|

Product Details:

Fiber Glass cloth is a prime elementary material made up of reinforcement of fiber glass yarn .

Fiber Glass cloth is light weight, versatile and non combutible material having properties of heat and corrosion resistance.

| Material | Fiber Glass |

| Type | Cloth |

| Colour | Silver |

| Thickness | 7mill |

| 5 Mill Thickness | 200 GSM |

| Width | 40” |

| Type of Weave | Plain Woven |

| Packing | Roll Form |

| USES: |

|

Product Details:

High quality fiber glass fabric is coated with flame retardant silicon rubber coating on one side two side. The fabric is superior for many application that requires chemical resistance, water proofing, fire proof, high strength, corrosion resistance and thermal insulation properties.

| USES: |

|

Product Details:

Bitumen laminated hessian cloth which is bonded with pastic with the help of Bitumen. Bitumenous Laminated Hessian Cloth is widely used for the purpose of packing of textile and non-textile products, specially for protecting costly equipment and goods from humidity and moisture during storage and transportation.

| Grades | Width | Quality of Hessian Cloth in OZ | Approx Weight (GSM) of Cloth only | Length of Roll |

| 38”(96.50 cm) | 5 OZ | 168 | 100 Yards | |

| 39”(99 cm) | 5.5 OZ | 153 | 100 Yards | |

| 40”(102 cm ) | 7 OZ | 210 | 100 Yards | |

| 44” (112 cm) | 7 OZ | 210 | 100 Yards | |

| USES: |

|

Product Details:

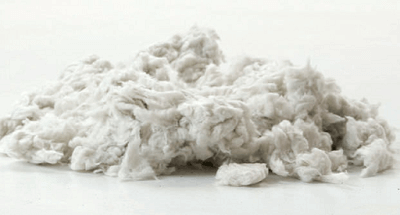

CAT – 9 is asbestos free inorganic mineral fiber combined with hydraulic cement annd chemically inert fillers.

CAT-9 Cement combines with water to form a general purpose protective coating with self-setting properties.

| Applied Density | 1200 to 1250 Kg/M3 |

| Box density | 750 to 800 KgM3 |

| Wet Covering Capacity | Approx 62 Sq. Mt per MT 12 mm thickness 125 Sq. Mt per MT for 6 mm thickness |

| Resistance to impact | 20-24 mm |

| Resistance to Compression | 4500-5000 KN/M2 |

| Flexural strength | 2800-3100 KN/M2 |

| Shrinkage | 0.18% maximum |

| Initial Set | With in 24 Hours |

| Final set | 20-25 days after laying |

| Drying Time | 48 Hours under Normal Condition up to 72 Hours under cold humid conditions |

| Temprature range | Up to 700 Deg C |

| Packing | 50 Kg Polythene lines hessian Bags |

| USES: |

|

Sheth Insulations Private Limited is a renowned suppliers of Aluminium jacketing insulation. Today we continue to be at the forefront of innovation by offering new products such as Energy Saving Ceiling Systems (ECS). We also offer customized service for projects with special requirements like windstorm resistant roofing systems or thermal barriers for difficult terrains. We are the leading fiberglass cloths supplier in India. The company was established in 1981 with an aim to supply and export different types of insulation products which are made from various materials. We offer a wide range of insulation solutions including supplying and exporting several types of fiberglass cloths.

"We are at SIPL, provide our customers with quality insulation materials at the most competitive price. Customer is the Priority, and their satisfaction is our aim."

City Office

705, Iconic Shyamal, Shyamal Char Rasta, Ahmedabad, Gujarat 380015

Godown Cum Office

No. 402/B, Phase- 2, G.I.D.C., Vatva, Ahmedabad, Gujarat, India - 382445