- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

- Home

- About Us

- Applications

- Applications

- Why Insulation

- Industrial application

- Building application

- Our Products

- Our Products

Why Insulation

Why Insulation

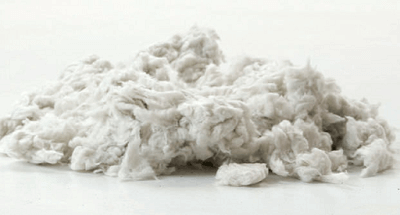

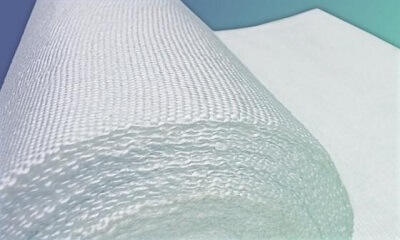

Thermal Insulation Material is the method used to help prevent or reduce the flow of heat. Put simply, thermal Insulation keeps Hot things hot and Cold things Cold. Energy loss is an inevitable consequence of contact between objects of different temperatures. Thermal insulation provides a means to maintain a gradient of temperature, in which energy flow is reduced or thermal radiation is reflected rather than absorbed. Thermal insulations are materials that insulate the components of mechanical systems in industrial process and buildings envelops.

Thermal Insulation Material is the method used to help prevent or reduce the flow of heat. Put simply, thermal Insulation keeps Hot things hot and Cold things Cold. Energy loss is an inevitable consequence of contact between objects of different temperatures.Thermal insulation provides a means to maintain a gradient of temperature, in which energy flow is reduced or thermal radiation is reflected rather than absorbed.

- Conserves Energy by Reducing Heat Loss or Gain -Properly designed and installed insulation systems immediately reduce the need for energy, a costly ingredient of every product made.

- Controls Surface Temperatures for Personnel Protection and Comfort -Insulation reduces the surface temperature of piping or equipment to a safer level, resulting in increased worker safety and the avoidance of worker downtime due to injury.

- Facilitates Process Temperature Control -By reducing heat loss or gain, insulation can help maintain the process temperature to a pre -determined value. Insulation thickness must be sufficient to limit the heat loss in a dynamic system or limit the temperature drop, with time, in a static system.

- Prevents Condensation on Cold Surfaces -Specifying sufficient insulation thickness with a good vapor barrier is the most effective means of controlling condensation and limiting corrosion on cold piping, ducts, chillers and roof drains. Sufficient thickness is needed to keep the surface temperature above the dew point temperature of the ambient air.

- Prevents or Reduces Damage to Equipment from Exposure to Fire or Corrosive Atmospheres -When used in combination with other materials, fiberglass and rock and slag wool insulation help provide fire protection in fire stop systems; grease & air-duct fireproofing; & electrical and communications conduit and cable protection.

- Controls Noise -Special or standard insulation materials can be used to encase or enclose a noise generating source, forming a sound barrier between the source and the surrounding area. Insulation installed in walls and ceilings can provide a barrier to the entry of sound from the outside or other rooms.

- Chemical Industries

- Petrochemical Refineries

- Solvent Extraction plants and oil industries

- Textile Industries

- Pharma / API & Biotech Industries

- Solar Plants

- Shipping and Marine Industries

- Cement Plant

- Fertilizer Plants

- Ceramic Industries

- Metal Industries

- Dairy and Cold Storages

- Power Generation Plant

- Any Building Commercial & Residential / HVAC Systems

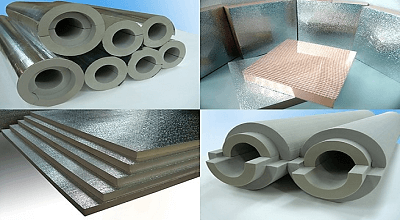

- Insulation Designing

- We carry out Thermal calculations,

- Design insulation thickness as per given criteria as per IS Standard

- Material Specification and execution:

- Material specification as per design

- Planning, Execution & Application @ site

- Design / Operating Temperature

- Installation cost / Payback

- Permissible Heat losses

- Fire Protection

- Anti Corrosive

- Chemical resistance

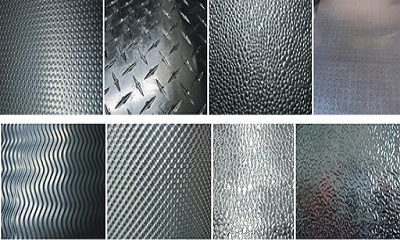

- Withstand atmospheric condition (Rain, Wind, storm )

- Preventing ingress of moisture

- Light weight

- Maintenance free

- Economical

- Payback time

Industrial application

Building application

"We are at SIPL, provide our customers with quality insulation materials at the most competitive price. Customer is the Priority, and their satisfaction is our aim."

City Office

705, Iconic Shyamal, Shyamal Char Rasta, Ahmedabad, Gujarat 380015

Godown Cum Office

No. 402/B, Phase- 2, G.I.D.C., Vatva, Ahmedabad, Gujarat, India - 382445